| Alkyl (40% C12, 50% C14, 10% C16) dimethyl benzyl ammonium chloride | 17.06% |

| Didecyl dimethyl ammonium chloride | 7.80% |

| Glutaraldehyde | 10.725% |

-

Virocid is a highly concentrated and broad spectrum disinfectant for use in food processing establishments, slaughter houses and livestock industries. Virocid is effective against: viruses, bacteria and fungi. Effective at rates as low as 0.25% (1:400). DIN 02239726 Active Ingredients

Virocid is a highly concentrated and broad spectrum disinfectant for use in food processing establishments, slaughter houses and livestock industries. Virocid is effective against: viruses, bacteria and fungi. Effective at rates as low as 0.25% (1:400). DIN 02239726 Active Ingredients -

Virocid is a highly concentrated and broad spectrum disinfectant for use in food processing establishments, slaughter houses and livestock industries. Virocid is effective against: viruses, bacteria and fungi. Effective at rates as low as 0.25% (1:400). DIN 02239726 Active Ingredients

Virocid is a highly concentrated and broad spectrum disinfectant for use in food processing establishments, slaughter houses and livestock industries. Virocid is effective against: viruses, bacteria and fungi. Effective at rates as low as 0.25% (1:400). DIN 02239726 Active IngredientsAlkyl (40% C12, 50% C14, 10% C16) dimethyl benzyl ammonium chloride 17.06% Didecyl dimethyl ammonium chloride 7.80% Glutaraldehyde 10.725% Directions For Use

To disinfect hard non-porous surfaces (livestock equipment, floors, walls, table tops, counter tops), apply a 0.25% (1:400) solution to thoroughly wet surface. Spray the surface and let stand for 10 minutes. Virocid is a concentrate that can be used with a mop and bucket, trigger sprayers, sponge, or by soaking. Heavily soiled surfaces should be precleaned prior to disinfection. All food contact surfaces must be thoroughly rinsed with potable water after disinfection.Storage

Store in original container, in a dry, cool place. Do not store in food processing environments.Disposal

1. Rinse the emptied container thoroughly and add the rinsings to the treatment site. 2. Follow local instructions for any required additional cleaning of the container prior to disposal. 3. Make the empty container unsuitable for further use. 4. Disposal of product and packaging: The product and packaging must be disposed of in accordance with local requirements.Precautions

KEEP OUT OF REACH OF CHILDREN. Danger - Corrosive to eyes. Do not get in eyes, on skin or clothing. Use appropriate clothes, gloves and eye protection. Harmful if swallowed. Avoid contamination of food.First Aid

In case of contact, immediately flush eyes or skin with plenty of water for at least 15 minutes. For eyes, call a physician. Remove and wash contaminated clothing before reuse. If inhaled, breathe fresh air and consult a physician. If swallowed, do NOT induce vomiting. Call a physician or poison control centre immediately. MSDS -

Virkon™ is a disinfectant, possessing wide spectrum virucidal, bactericidal and fungicidal activity. The effectiveness of Virkon™ is further enhanced by its excellent detergent properties, so that clean disease-free surfaces can be achieved. Virkon™ is unique in its composition. Its activity is based on a buffered synergized acid peroxygen system containing a high percentage of surfactant. Virkon™ can be used on all surfaces and in all situations. Once diluted in a 1% solution, Virkon™ is of low toxicity, non-tainting, and non-irritant. Because of its high detergency and mode of action, Virkon™ can be used in an exceptional variety of situations for effective cleaning and virucidal disinfection in a single operation. Virkon™ can be applied manually or through all types of cleaning and spraying equipment. Readily soluble in lukewarm water giving a clear pink solution. Virkon™ consists mainly of inorganic salts. DIN 02125021 Active Ingredients

Virkon™ is a disinfectant, possessing wide spectrum virucidal, bactericidal and fungicidal activity. The effectiveness of Virkon™ is further enhanced by its excellent detergent properties, so that clean disease-free surfaces can be achieved. Virkon™ is unique in its composition. Its activity is based on a buffered synergized acid peroxygen system containing a high percentage of surfactant. Virkon™ can be used on all surfaces and in all situations. Once diluted in a 1% solution, Virkon™ is of low toxicity, non-tainting, and non-irritant. Because of its high detergency and mode of action, Virkon™ can be used in an exceptional variety of situations for effective cleaning and virucidal disinfection in a single operation. Virkon™ can be applied manually or through all types of cleaning and spraying equipment. Readily soluble in lukewarm water giving a clear pink solution. Virkon™ consists mainly of inorganic salts. DIN 02125021 Active IngredientsPotassium monopersulfate 21.4% W/W Directions For Use

In agricultural buildings: animals must be removed from the premise during disinfection. In food processing plants: for food contact surfaces, rinse thoroughly with potable water after disinfection. 1. FOR CLEANING AND DISINFECTION OF SURFACES AND EQUIPMENT: In agricultural buildings Remove all animals from premises. Remove all litter and manure from floors, walls, and other surfaces of barns and equipment. Brush and blow dust from fans, motors, louvers and electrical equipment. For terminal cleaning and disinfection, saturate all surfaces with a 1% w/v solution of Virkon™, using a pressure washer or a fogger. Virkon™ should remain in contact with the surface to be disinfected for at least 10 minutes. Scrub heavily soiled utensils and soak in a 1% w/v solution of Virkon™ for 10 minutes (do not exceed 30 minutes for metal objects). In veterinary hospitals Remove heavy soil deposits then thoroughly wet surfaces to be disinfected with a 1% w/v solution of Virkon™, using a mop, sponge or cloth, as well as by spraying. A minimum contact time of 10 minutes is required. For laboratory equipment and bowls, scrub heavily soiled utensils and soak in a 1% w/v solution of Virkon™ for a minimum of 10 minutes (do not exceed 30 minutes for metal objects). IMPORTANT NOTE: In animal premises where there has been a disease outbreak and/or the mortality/morbidity rates are higher than normal and the causative agent has been determined by a pathology laboratory to be one of those listed in Table 1, the contact time/dilution rate indicated should be used. In food processing plants Remove all debris and other deposits from surfaces. Then, thoroughly wet surfaces to be disinfected with a 1% w/v solution of Virkon™, using a mop, sponge or cloth, as well as by spraying. A minimum contact time of 10 minutes is required. For food contact surfaces, rinse thoroughly with potable water after treatment with Virkon™. For a complete listing of microorganisms against which Virkon™ is effective, refer to the Efficacy Charts 2, 3, and 4. 2. FOR AERIAL DISINFECTION: To replace dangerous and ineffective formalin fumigation in empty farm buildings and veterinary hospitals. Shutdown the ventilation system during the disinfection. Use a mechanical fogging machine as part of terminal disinfection routine with a 1% w/v solution of Virkon™. Apply at a rate of one litre of solution per 100 m3 with particle size not exceeding 70 microns in order to get a minimal contact time of 10 minutes with microorganisms in the air. Leave the room during the fogging. Users and animals may re-enter the treated area once the fog has dispersed. No rinsing is required after fogging. 3. SANITIZING DRINKING WATER SYSTEM: For sanitizing drinking water system at terminal clean out, use a 1.0% w/v solution of Virkon™. Dose header tank and drain system. Wait at least 10 minutes before draining again. DILUTION INSTRUCTIONS1) Select the quantity of disinfectant solution required. 2) Choose appropriate dilution rate. 3) Measure out the amount of Virkon™ indicated using the graduated measuring scoop provided. 4) Add Virkon™ to warm water and stir. There is a 20% loss of activity of 1% solutions of Virkon™ after 14 days in 350 ppm hard water.Dilution rate required (w/v) Quantity of disinfectant solution required 3.0% 2.0% 1.0% 0.5% 0.2% Quantity of Virkon™ required 30 g 20 g 10 g 5 g 2 g 1 Litre 150 g 100 g 50 g 25 g 10 g 5 Litres 300 g 200 g 100 g 50 g 20 g 10 Litres 750 g 500 g 250 g 125 g 50 g 25 Litres Storage

Store between 15°C and 25°C in a dry place in tightly sealed containers.Disposal

1) Rinse the emptied container thoroughly and add the rinsings to treatment site. 2) Follow provincial instructions for any required additional cleaning of the container prior to its disposal. 3) Make the empty container unsuitable for further use. 4) Dispose of the container in accordance with provincial requirements. 5) For information on the disposal of unused, unwanted product and the cleanup of spills, contact the Provincial Regulatory Agency or the Manufacturer.Precautions

Keep out of reach of children. Powder irritating to eyes, skin and mucous membranes. May be harmful if swallowed or inhaled. Do not get powder in eyes. Avoid contact of powder with skin. Handle in such a way as to minimize dust release. Do not mix with other chemicals. When mixing the solution, wear goggles, chemical-resistant gloves, and a mask. It is recommended that workers wear overalls, goggles and a mask when applying Virkon™ solution with a hand-held fogger or a pressure washer.First Aid

Eyes: Irrigate with plenty of water. Skin: When in powder, remove contaminated clothing. Wash with soap and water. Not hazardous when in solution. Ingestion: When in powder, wash mouth with plenty of water. Drink plenty of water. Do not induce vomiting. Seek medical advice. If in solution, rinse mouth out with water. Inhalation: When in powder, if symptoms of coughing, choking, wheezing are troublesome, remove to fresh air and seek medical advice. MSDS -

Virkon™ is a disinfectant, possessing wide spectrum virucidal, bactericidal and fungicidal activity. The effectiveness of Virkon™ is further enhanced by its excellent detergent properties, so that clean disease-free surfaces can be achieved. Virkon™ is unique in its composition. Its activity is based on a buffered synergized acid peroxygen system containing a high percentage of surfactant. Virkon™ can be used on all surfaces and in all situations. Once diluted in a 1% solution, Virkon™ is of low toxicity, non-tainting, and non-irritant. Because of its high detergency and mode of action, Virkon™ can be used in an exceptional variety of situations for effective cleaning and virucidal disinfection in a single operation. Virkon™ can be applied manually or through all types of cleaning and spraying equipment. Readily soluble in lukewarm water giving a clear pink solution. Virkon™ consists mainly of inorganic salts. DIN 02125021 Active Ingredients

Virkon™ is a disinfectant, possessing wide spectrum virucidal, bactericidal and fungicidal activity. The effectiveness of Virkon™ is further enhanced by its excellent detergent properties, so that clean disease-free surfaces can be achieved. Virkon™ is unique in its composition. Its activity is based on a buffered synergized acid peroxygen system containing a high percentage of surfactant. Virkon™ can be used on all surfaces and in all situations. Once diluted in a 1% solution, Virkon™ is of low toxicity, non-tainting, and non-irritant. Because of its high detergency and mode of action, Virkon™ can be used in an exceptional variety of situations for effective cleaning and virucidal disinfection in a single operation. Virkon™ can be applied manually or through all types of cleaning and spraying equipment. Readily soluble in lukewarm water giving a clear pink solution. Virkon™ consists mainly of inorganic salts. DIN 02125021 Active IngredientsPotassium monopersulfate 21.4% W/W Directions For Use

In agricultural buildings: animals must be removed from the premise during disinfection. In food processing plants: for food contact surfaces, rinse thoroughly with potable water after disinfection. 1. FOR CLEANING AND DISINFECTION OF SURFACES AND EQUIPMENT: In agricultural buildings Remove all animals from premises. Remove all litter and manure from floors, walls, and other surfaces of barns and equipment. Brush and blow dust from fans, motors, louvers and electrical equipment. For terminal cleaning and disinfection, saturate all surfaces with a 1% w/v solution of Virkon™, using a pressure washer or a fogger. Virkon™ should remain in contact with the surface to be disinfected for at least 10 minutes. Scrub heavily soiled utensils and soak in a 1% w/v solution of Virkon™ for 10 minutes (do not exceed 30 minutes for metal objects). In veterinary hospitals Remove heavy soil deposits then thoroughly wet surfaces to be disinfected with a 1% w/v solution of Virkon™, using a mop, sponge or cloth, as well as by spraying. A minimum contact time of 10 minutes is required. For laboratory equipment and bowls, scrub heavily soiled utensils and soak in a 1% w/v solution of Virkon™ for a minimum of 10 minutes (do not exceed 30 minutes for metal objects). IMPORTANT NOTE: In animal premises where there has been a disease outbreak and/or the mortality/morbidity rates are higher than normal and the causative agent has been determined by a pathology laboratory to be one of those listed in Table 1, the contact time/dilution rate indicated should be used. In food processing plants Remove all debris and other deposits from surfaces. Then, thoroughly wet surfaces to be disinfected with a 1% w/v solution of Virkon™, using a mop, sponge or cloth, as well as by spraying. A minimum contact time of 10 minutes is required. For food contact surfaces, rinse thoroughly with potable water after treatment with Virkon™. For a complete listing of microorganisms against which Virkon™ is effective, refer to the Efficacy Charts 2, 3, and 4. 2. FOR AERIAL DISINFECTION: To replace dangerous and ineffective formalin fumigation in empty farm buildings and veterinary hospitals. Shutdown the ventilation system during the disinfection. Use a mechanical fogging machine as part of terminal disinfection routine with a 1% w/v solution of Virkon™. Apply at a rate of one litre of solution per 100 m3 with particle size not exceeding 70 microns in order to get a minimal contact time of 10 minutes with microorganisms in the air. Leave the room during the fogging. Users and animals may re-enter the treated area once the fog has dispersed. No rinsing is required after fogging. 3. SANITIZING DRINKING WATER SYSTEM: For sanitizing drinking water system at terminal clean out, use a 1.0% w/v solution of Virkon™. Dose header tank and drain system. Wait at least 10 minutes before draining again. DILUTION INSTRUCTIONS1) Select the quantity of disinfectant solution required. 2) Choose appropriate dilution rate. 3) Measure out the amount of Virkon™ indicated using the graduated measuring scoop provided. 4) Add Virkon™ to warm water and stir. There is a 20% loss of activity of 1% solutions of Virkon™ after 14 days in 350 ppm hard water.Dilution rate required (w/v) Quantity of disinfectant solution required 3.0% 2.0% 1.0% 0.5% 0.2% Quantity of Virkon™ required 30 g 20 g 10 g 5 g 2 g 1 Litre 150 g 100 g 50 g 25 g 10 g 5 Litres 300 g 200 g 100 g 50 g 20 g 10 Litres 750 g 500 g 250 g 125 g 50 g 25 Litres Storage

Store between 15°C and 25°C in a dry place in tightly sealed containers.Disposal

1) Rinse the emptied container thoroughly and add the rinsings to treatment site. 2) Follow provincial instructions for any required additional cleaning of the container prior to its disposal. 3) Make the empty container unsuitable for further use. 4) Dispose of the container in accordance with provincial requirements. 5) For information on the disposal of unused, unwanted product and the cleanup of spills, contact the Provincial Regulatory Agency or the Manufacturer.Precautions

Keep out of reach of children. Powder irritating to eyes, skin and mucous membranes. May be harmful if swallowed or inhaled. Do not get powder in eyes. Avoid contact of powder with skin. Handle in such a way as to minimize dust release. Do not mix with other chemicals. When mixing the solution, wear goggles, chemical-resistant gloves, and a mask. It is recommended that workers wear overalls, goggles and a mask when applying Virkon™ solution with a hand-held fogger or a pressure washer.First Aid

Eyes: Irrigate with plenty of water. Skin: When in powder, remove contaminated clothing. Wash with soap and water. Not hazardous when in solution. Ingestion: When in powder, wash mouth with plenty of water. Drink plenty of water. Do not induce vomiting. Seek medical advice. If in solution, rinse mouth out with water. Inhalation: When in powder, if symptoms of coughing, choking, wheezing are troublesome, remove to fresh air and seek medical advice. MSDS -

For an outstanding, highly durable elastic-topped boot, the Treader™ line of disposable boots is the way to go. The Treader™ boot’s unique pyramid-shaped treads not only increase wear and durability, they can also be an advantage on slipper surfaces where footing can be precarious. The tread pattern more than tripples the thickness of the sole of these disposable boots – the highest wear area and usually the first part of the boot to fail – making Treaders™ one of the most durable boots on the market.

For an outstanding, highly durable elastic-topped boot, the Treader™ line of disposable boots is the way to go. The Treader™ boot’s unique pyramid-shaped treads not only increase wear and durability, they can also be an advantage on slipper surfaces where footing can be precarious. The tread pattern more than tripples the thickness of the sole of these disposable boots – the highest wear area and usually the first part of the boot to fail – making Treaders™ one of the most durable boots on the market. -

For control of crawling, flying, and wood destroying insect pests on indoor surfacesMSDS

For control of crawling, flying, and wood destroying insect pests on indoor surfacesMSDSGUARANTEE: Cyfluthrin 20% Directions For Use:

Read these entire Directions for Use before using Tempo 20 WP Insecticide. Do not formulate this product into other end-use products.General Information

Tempo 20 WP Insecticide contains 20% active ingredient, which will provide effective knockdown and residual control of the pests listed on the label. One level Tempo scoop or 4 level teaspoons contain 9.5 grams of Tempo 20 WP Insecticide. Do not use scoop or teaspoon for feed, food, or drinking water purposes. Tempo 20 WP Insecticide is intended for use as an indoor spot, or crack and crevice application in Dwellings, such as apartments, hospitals, hotels, houses and nursing homes; Institutions, such as factories, laboratories, mausoleums, non-commercial greenhouses, schools, stores and warehouses; Modes of transport, such as aircraft, buses, rail cars, ships and trucks; Food/feed establishments, such as bakeries, bottling plants, canneries, dairies, frozen food plants, grain mills, kitchens, meat packing plants, poultry and egg processing plants and restaurants; and Pet kennels. Tempo 20 WP Insecticide also is intended for use as a general surface spray for control of flying and crawling insects in livestock housing structures, including poultry houses. Tempo 20 WP Insecticide is intended to be mixed with water and applied with hand pressurized or power operated sprayers. Spray pressure should not exceed 345 KPa (50 psi) at the nozzle tip when used indoors. Add the appropriate amount of product when filling sprayer tank with water, shake or agitate as necessary to mix. Diluted spray mixture can be stored overnight and applied the following day, but the mixture should be agitated before spraying to prevent uneven distribution of product. Before leaving spray mixture unagitated for an extended period of time, release tank pressure and elevate nozzle and hose above tank outlet, activate trigger and drain all suspension from hose back into spray tank. Re-tighten spray tank lid and do not re-pressurize until starting to spray again. Tempo 20 WP Insecticide will not stain or cause damage to any painted or varnished household surface, plastic, fabric or other surface where water applied alone causes no damage.Spot, Crack And Crevice Applications

Mix one level Tempo scoop of Tempo 20 WP Insecticide in 3.75L of water to make a 0.05% active ingredient suspension. Under conditions of severe pest infestation or when longer residual control is needed, mix two level Tempo scoops of Tempo 20 WP Insecticide in 3.75L of water to make a 0.1% active ingredient suspension. Use a low pressure system with a pin-point or variable pattern nozzle to apply the suspension in specific areas such as cracks and crevices in or behind baseboards, in floors, walls, expansion joints, areas around water and sewer pipes, wall voids, or voids in table legs and equipment where pests can hide. Tempo 20 WP Insecticide can be reapplied at 10-day intervals, if necessary. Do not apply where electrical short circuits could occur. Use a dust or dry bait in these areas. Spot treatment with a low pressure coarse spray may be made ONLY to localized areas along baseboards; beneath and behind sinks, stoves, refrigerators and cabinets; around plumbing and other utility installations; around doors and windows. A spot is an area no larger than 0.2m2. NOTE: CARE SHOULD BE TAKEN TO AVOID DEPOSITING THE PRODUCT ONTO SURFACES WHICH ARE EASILY ACCESSIBLE BY CHILDREN.Food/feed Establishments:

Tempo 20 WP Insecticide applications are permitted in both food and non-food areas of food/feed handling establishments as a spot, or crack and crevice treatment. Food/feed establishments are defined as places other than private residences in which exposed food or feed is held, processed, prepared or served. Included also are areas for receiving, storing, packing (canning, bottling, wrapping, boxing), preparing, edible waste storage and enclosed processing systems (mills, dairies, edible oils, syrups) for food or feed. Serving areas where food is exposed and the facility is in operation are also considered food areas. Application in food handling areas of the facility may be made during close-down periods only. Do not apply directly to food or food-handling surfaces. Cover or remove all food processing and/or handling equipment before application. After application in food processing plants, bakeries, cafeterias and similar facilities, wash all equipment, benches, shelving and other surfaces which food will contact. Clean food handling or processing equipment and thoroughly rinse with clean, fresh water. Dwellings, Institutions and Modes of Transport: For general household pests and occasional invaders make applications in a manner as previously described under Spot, Crack and Crevice Application. Particular attention should be given to treating entry points and harbourage areas. Remove or tightly cover fish tanks and disconnect aerators during application. Bystanders and animals must be excluded during applications of Tempo 20 WP Insecticide, and not allowed to re-enter treated areas until at least two hours afterwards. For pantry pest control of exposed adult and immature stages of insects, make application to cupboards, shelving and storage areas. Particular attention should be given to treating cracks and crevices. Remove all utensils, uncovered foodstuffs (or any with package opened), shelf paper and other objects before spraying. Allow treated surfaces to dry and cover shelves with clean paper before replacing any utensils, foodstuff or other items. Any foodstuff accidentally contaminated with spray solution should be discarded. For stored product pest control of exposed adult and immature stages of insect pests, apply to cracks, crevices, and other surfaces where the pests have been seen or have harbourage. Treat warehouses, production facilities, storage areas, rail cars, truck beds and other areas where products are stored before filling with the product. Tempo 20 WP Insecticide may be used by pest control operators and grain producers to treat grain storage facilities and other areas noted above for stored product pest control. Cleaning of all areas prior to use of Tempo 20 WP Insecticide will increase levels of control. Any foodstuffs infested with pests should be removed and destroyed. For premises pest control make spot application in closets and storage areas where these pests normally feed or hide. Follow all precautions listed above for general household pests. For control of carpet beetles, apply as a spot treatment along baseboards and edges of carpeting, under carpets and rugs, in closets and on shelving. For control of flying insects indoors, apply as a spot treatment on window frames. Do not apply as a “space spray”. For control of carpenter ants in houses and other structures, use a 0.1% suspension and apply as a spot, crack and crevice or wall void application. Repeat treatments when necessary. Apply around doors and windows. Spray into cracks and crevices or through small drilled holes into voids where these ants or their nests are present. Do not exceed 30 to 50 mL of dilute suspension per m2 of treated surface. For aircraft pest control apply to cracks, crevices and other surfaces where the pests have been seen or have harbourage. Applications should not be made when passengers or non-essential personnel are present in the immediate or treated area. Passengers or other personnel should not be allowed to enter treated areas until at least two hours after application. Do not use in aircraft cabins. Do not allow spray to contact electrical and electronic systems. Pet Kennels: For use in pet kennels to control flying and crawling insects: apply as a spot or crack and crevice spray. Control will be enhanced when facilities are cleaned. Do not make applications of Tempo 20 WP Insecticide when animals are present in area of facility to be treated. Allow at least two hours after application before re-stocking treated area of the facility. Cover or remove animal feedstuffs or watering equipment.General Surface Applications

Livestock Housing (including Poultry Houses):

For use by pest control operators and livestock producers in livestock housing structures (including poultry houses) to control crawling and flying insect pests. For control of flies apply as a general surface spray using 1 or 2 level scoops of Tempo 20 WP Insecticide per 100 m2 in sufficient water to adequately cover the area being treated, but which will not allow dripping or run-off to occur. Use the higher rate when infestation is severe or when longer residual control is needed. Use a low pressure spray system with a fan-type nozzle to uniformly apply the suspension. Control will be enhanced if facilities are cleaned. Applications can be made to all fly resting surfaces such as walls, ceilings, posts, rafters, windows, dividers, stanchions, gates, bunks, curtains, etc. Full protective clothing is recommended, including a hat (preferably safety helmet with visor), safety glasses, goggles or face shield, respirator, long-sleeved coveralls, unlined rubber gloves and rubber boots. Do not apply Tempo 20 WP Insecticide when animals are present in area of facility to be treated. Apply only in well ventilated areas. Do not allow cattle to re-enter facilities within 2 hours following application and poultry within 24 hours following application. Cover watering bowls in dairy barns securely with a tight fitting, elastic banded plastic cover. Cover feeding troughs in dairy barns securely with heavy plastic (6 mil) with sufficient plastic to allow for a 6” overhang on the sides of the trough. Avoid direct spray application to the plastic used to cover bowls and troughs. Allow two hours after application before restocking treated area of facility. Do not apply where electrical short circuits could occur. Do not apply as a “space spray”. For control of crawling pests (see list) apply as a surface spray (see all the above directions and precautions for fly control) and/or as a crack and crevice application (0.05-0.1% active ingredient suspension) to areas where the insects occur. For control of lesser mealworm (adults and larvae) in poultry houses apply after clean-out and before fresh litter is put down. Do not add fresh litter until at least one day after spraying.Resistance Management Recommendations

For resistance management, please note that Tempo 20 WP Insecticide contains a Group 3 insecticide. Any insect population may contain individuals naturally resistant to Tempo 20 WP Insecticide and other Group 3 insecticides. The resistant individuals may dominate the insect population if this group of insecticides are used repeatedly in the same fields. Other resistance mechanisms that are not linked to site of action but are specific for individual chemicals, such as enhanced metabolism, may also exist. Appropriate resistance-management strategies should be followed. To delay insecticide resistance: ● Where possible, rotate the use of Tempo 20 WP Insecticide or other Group 3 insecticides with different groups that control the same pests in the field. ● Use tank mixtures with insecticides from a different group when such use is permitted. ● Insecticide use should be based on an IPM program that includes scouting, record keeping, and considers cultural, biological and other chemical control practices. ● Monitor treated pest populations for resistance development. PESTS CONTROLLED BY Tempo 20 WP Insecticide 1. Crawling Pests Ants (except Pharaoh) Bedbug Carpet beetles Cockroaches American German Oriental Crickets Lesser Mealworm (adults & larvae) Earwigs Firebrat Sowbugs Spiders 2. Flying Pests Flies Mosquitoes Wasps 3. Pantry & Stored Product Pests Beetles (exposed adults & immature stages): Confused flour Warehouse Moths: Indian meal (larvae only) 4. Wood Infesting Pests Carpenter antsEnvironmental Hazards

This pesticide is extremely toxic to fish and aquatic invertebrates. Remove from premises or tightly cover fish tanks and disconnect aerators when applying indoors where such containers are present. Do not contaminate water when disposing of equipment wash waters. Apply this product only as specified on the label.First Aid

If in eyes: hold eye open and rinse slowly and gently with water for 15-20 minutes. Remove contact lenses, if present, after the first 5 minutes, then continue rinsing eye. Call a poison control centre or doctor for treatment advice. If swallowed: Call a poison control centre or doctor immediately for treatment advice. Have a person sip a glass of water if able to swallow. Do not induce vomiting unless told to do so by a poison control centre or doctor. Do not give anything by mouth to an unconscious person. If on skin or clothing: Take off contaminated clothing. Rinse skin immediately with plenty of water for 15-20 minutes. Call a poison control centre or doctor for treatment advice. If inhaled: Move person to fresh air. If person is not breathing, call 911 or an ambulance, then give artificial respiration, preferably by mouth-to mouth, if possible. Call a poison control centre or doctor for further treatment. Take container, label or product name and Pest Control Product Registration Number with you when seeking medical attention. TOXICOLOGICAL INFORMATION: Symptoms of poisoning may include itching, tautness and reddening of facial skin, paraesthesia (elevated sensitivity, particularly to touch) and irritation of the eyes, mouth and throat. No specific antidote is available. Avoid alcohol. Treat the patient symptomatically.Storage And Disposal

Not for storage in or around the house. Store in a cool, dry place and in such a manner as to prevent cross contamination with other pesticides, fertilizers, food, and feed. Store in original container and out of the reach of children. Do not contaminate water, food, or feed by storage or disposal. Disposal of Container: Do not reuse this container for any purpose. This is a recyclable container, and is to be disposed of at a container collection site. Contact your local distributor/dealer or municipality for the location of the nearest collection site. Before taking the container to the collection site: 1. Triple- or pressure-rinse the empty container. Add the rinsings to the spray mixture in the tank. 2. Make the empty, rinsed container unsuitable for further use. If there is no container collection site in your area, dispose of the container in accordance with provincial requirements. For information on disposal of unused, unwanted product, contact the manufacturer or the provincial regulatory agency. Contact the manufacturer and the provincial regulatory agency in case of a spill, and for clean-up of spills. -

Stalosan F is designed to uniquely meet the hygiene needs of the modern poultry industry. It kills a wide range of pathogens, including bacteria, viruses, fungi, parasites, and flies. Stalosan F also plays an important role in your birds’ environment as a litter conditioner. It is effective in improving air quality and neutralizing harmful substances such as ammonia and hydrogen sulfide. MSDS

Stalosan F is designed to uniquely meet the hygiene needs of the modern poultry industry. It kills a wide range of pathogens, including bacteria, viruses, fungi, parasites, and flies. Stalosan F also plays an important role in your birds’ environment as a litter conditioner. It is effective in improving air quality and neutralizing harmful substances such as ammonia and hydrogen sulfide. MSDS -

This treatment applies to the following species: -Chickens -Turkeys CFIA Registration No T983937

This treatment applies to the following species: -Chickens -Turkeys CFIA Registration No T983937Guaranteed Analysis:

Copper (min) 12.9 %, Sulfur (min) 6 %, Lead (max) 10.2 mg/kg, Arsenic (max) 4.1 mg/kg, Iron (max) 255 mg/kgList of Ingredients:

Cupric Sulfate (as pentahydrate), USP, 51% w/w, Citric AcidDirections for Use

Dissolve 500 g in 4L of drinking water as a premix (stock) solution. Then give this premix at the rate of 30 mL per 9L of water. Period of use as directed by a veterinarian. Prepare fresh solutions daily.Storage

Keep in a cool dry place. Store below 25 ˚C. Keep from freezing.Caution

Mix thoroughly. Only use according to instructions. Wear protective clothing when handling. Net Weight 10kg pail -

Revolver® soft bait provides a highly palatable formulation of the most widely used active ingredient, Bromadiolone. It is the solution when rotating to a Bromadiolone rodenticide in your biosecurity rodent control program. Revolver contains no wax, increasing palatability and results, in a low-cost per placement 12 gram (0.42 oz.) pouch. Food-grade oils and grains produce an aroma attracting rodents away from competing food sources, providing strong knock-down control of the toughest rodent populations. When compared to competitive green wax-blocks, Revolver no-wax soft bait outperforms and delivers increased palatability, with no bait melt in high temperatures, making it the superior Bromadiolone rodenticide in your bait rotation. No-wax soft bait pouches are easy to use and allow tailored dosing to control heavy rodent infestations or as a low cost per placement monitoring bait, saving producers money and bait waste. Revolver pouches can also be used like a conventional mini-block anchored in a bait station, or end-users can strategically place this unique presentation in tight, hard to reach places where mini-blocks will not fit, targeting where rodents live and reproduce. MSDS

Revolver® soft bait provides a highly palatable formulation of the most widely used active ingredient, Bromadiolone. It is the solution when rotating to a Bromadiolone rodenticide in your biosecurity rodent control program. Revolver contains no wax, increasing palatability and results, in a low-cost per placement 12 gram (0.42 oz.) pouch. Food-grade oils and grains produce an aroma attracting rodents away from competing food sources, providing strong knock-down control of the toughest rodent populations. When compared to competitive green wax-blocks, Revolver no-wax soft bait outperforms and delivers increased palatability, with no bait melt in high temperatures, making it the superior Bromadiolone rodenticide in your bait rotation. No-wax soft bait pouches are easy to use and allow tailored dosing to control heavy rodent infestations or as a low cost per placement monitoring bait, saving producers money and bait waste. Revolver pouches can also be used like a conventional mini-block anchored in a bait station, or end-users can strategically place this unique presentation in tight, hard to reach places where mini-blocks will not fit, targeting where rodents live and reproduce. MSDS -

Revolver® soft bait provides a highly palatable formulation of the most widely used active ingredient, Bromadiolone. It is the solution when rotating to a Bromadiolone rodenticide in your biosecurity rodent control program. Revolver contains no wax, increasing palatability and results, in a low-cost per placement 12 gram (0.42 oz.) pouch. Food-grade oils and grains produce an aroma attracting rodents away from competing food sources, providing strong knock-down control of the toughest rodent populations. When compared to competitive green wax-blocks, Revolver no-wax soft bait outperforms and delivers increased palatability, with no bait melt in high temperatures, making it the superior Bromadiolone rodenticide in your bait rotation. No-wax soft bait pouches are easy to use and allow tailored dosing to control heavy rodent infestations or as a low cost per placement monitoring bait, saving producers money and bait waste. Revolver pouches can also be used like a conventional mini-block anchored in a bait station, or end-users can strategically place this unique presentation in tight, hard to reach places where mini-blocks will not fit, targeting where rodents live and reproduce. MSDS

Revolver® soft bait provides a highly palatable formulation of the most widely used active ingredient, Bromadiolone. It is the solution when rotating to a Bromadiolone rodenticide in your biosecurity rodent control program. Revolver contains no wax, increasing palatability and results, in a low-cost per placement 12 gram (0.42 oz.) pouch. Food-grade oils and grains produce an aroma attracting rodents away from competing food sources, providing strong knock-down control of the toughest rodent populations. When compared to competitive green wax-blocks, Revolver no-wax soft bait outperforms and delivers increased palatability, with no bait melt in high temperatures, making it the superior Bromadiolone rodenticide in your bait rotation. No-wax soft bait pouches are easy to use and allow tailored dosing to control heavy rodent infestations or as a low cost per placement monitoring bait, saving producers money and bait waste. Revolver pouches can also be used like a conventional mini-block anchored in a bait station, or end-users can strategically place this unique presentation in tight, hard to reach places where mini-blocks will not fit, targeting where rodents live and reproduce. MSDS -

A flavouring agent for drinking water for swine, broilers, layers, turkeys and calves. Ingredients: Water, guar gum, origanum oil, xanthan gum. Directions for use: Mix Regano CL5 at the following rates per liter of stock solution. Note: One liter of stock solution needs to be metered with 128 liters of water.

A flavouring agent for drinking water for swine, broilers, layers, turkeys and calves. Ingredients: Water, guar gum, origanum oil, xanthan gum. Directions for use: Mix Regano CL5 at the following rates per liter of stock solution. Note: One liter of stock solution needs to be metered with 128 liters of water.Swine Boars 20mL Sows 35mL Finishers 35mL Growers 50mL Starters 70mL Piglets 128mL Calves: (Up to 60kg body weight) 0.25 - 0.30 mLPoultry Broilers 50mL Layers 25mL Turkeys 45mL -

The Quick-Mix pump is designed to accurately dose disinfectants through your water lines. The unique injection system makes it easy to dose disinfectants at 2 or 3% without having to worry about harsh chemicals wrecking diaphragms. To change the dilution ratio simply change the metering tip to the desired strength. Comes with tips for Proxy-Clean, Hyperox, Virocid and many other disinfectants. The quick-Mix is a wall mounted, push button dispenser.

The Quick-Mix pump is designed to accurately dose disinfectants through your water lines. The unique injection system makes it easy to dose disinfectants at 2 or 3% without having to worry about harsh chemicals wrecking diaphragms. To change the dilution ratio simply change the metering tip to the desired strength. Comes with tips for Proxy-Clean, Hyperox, Virocid and many other disinfectants. The quick-Mix is a wall mounted, push button dispenser.- Ideal for cleaning waterlines between flocks

- Garden hose connection

- Twist Lock

- Compatible with most common chemicals

- No power needed

- No Diaphragms

- Affordable, low maintenance unit

- Flow Rate - requires at least (3.5GPM)

- Compatible with chlorine, Hydrogen peroxide & more.

-

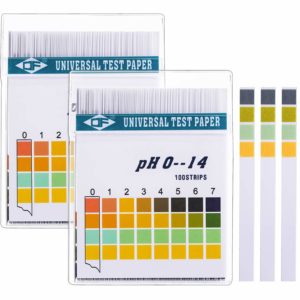

PWT livestock water treatment contains the strongest animal feed grade mineral acid available. A much lower addition rate is required to acidify drinking water to low pH levels. This lower addition rate provides pH reduction with no bitter taste. Birds and livestock won’t back off from PWT treated water, so optimum water consumption is maintained. MSDS

PWT livestock water treatment contains the strongest animal feed grade mineral acid available. A much lower addition rate is required to acidify drinking water to low pH levels. This lower addition rate provides pH reduction with no bitter taste. Birds and livestock won’t back off from PWT treated water, so optimum water consumption is maintained. MSDS -

Proxy-Clean is a stabilized hydrogen peroxide based product specially formulated to remove and prevent heavy soils in livestock operations of any size. Proxy-Clean utilizes a proprietary stabilizer that is an active ingredient not found in any other product. The stabilizers used in other hydrogen peroxide products just allow them to be shelf stable. Proxy-Clean’s proprietary stabilizer acts as a decomposition catalyst allowing Proxy-Clean to do a complete cleaning on water lines and watering systems. Active IngredientsStabilized Hydrogen peroxide: 50% W/W.

Proxy-Clean is a stabilized hydrogen peroxide based product specially formulated to remove and prevent heavy soils in livestock operations of any size. Proxy-Clean utilizes a proprietary stabilizer that is an active ingredient not found in any other product. The stabilizers used in other hydrogen peroxide products just allow them to be shelf stable. Proxy-Clean’s proprietary stabilizer acts as a decomposition catalyst allowing Proxy-Clean to do a complete cleaning on water lines and watering systems. Active IngredientsStabilized Hydrogen peroxide: 50% W/W.Directions For Use

With Animals Present Mix Proxy-Clean with water to create the following stock solutions:

Discontinue use of any medication, chlorine or sanitizer when administering Proxy Clean. Resume the use of chlorine or other sanitizers after Proxy Clean treatment is finished. For routine sanitation use Proxy Clean at 25-50ppm in the drinking water (use test strips to measure concentration). Between 2 Lots/No Animals Present Fill the water lines with a Proxy Clean/water solution using the following options: Option 1: Use a 1:100 or 1:128 medicator to fill the water lines with a 1% or 0.78% solution of Proxy Clean. Allow the solution to remain in the water lines for a minimum of 48 hours before flushing. Option 2: Use a 3:100 medicator to fill the water lines with a 3% solution of Proxy Clean. Allow the solution to remain in the water lines for a minimum of 12 hours before flushing. When using Proxy Clean make sure that there is an adequate air release from your water system.Pump Water Proxy Clean Days 1 & 2 3 & 4 5 & 6 7-10 1:100 20L 250mL 350mL 475mL 600mL 1:128 20L 320mL 450mL 600mL 775mL Storage & Disposal

Please refer to MSDS sheet.Precautions & First Aid

Please refer to MSDS sheet. MSDS -

PLT® – More Than Ammonia Control

PLT®-Poultry Litter Treatment has proven to be the most effective and economical litter acidifier available. PLT lowers litter pH and creates a beneficial environment in the poultry house by controlling ammonia released from the litter. The ammonia bound by PLT reduces environmental emissions and increases the nutrient value of poultry manure. Flexible. PLT can be used in any litter-based commercial poultry operation including those that grow broilers, breeders, turkeys, commercial pullets and layers, quail, pheasants and ducks. Easy & Safe Application. PLT can be applied using any type of spreader and it can be safely applied with birds in the house. Plus, PLT is the only litter amendment that is classified as non-hazardous by the DOT and non-corrosive. Fuel Savings. By immediately binding ammonia, PLT decreases ventilation needs, which reduces fuel costs. Valuable Poultry Manure. By turning volatile ammonia into stable ammonium sulfate, the value of the poultry manure increases. Backed by Experts. PLT® is backed by an expert team with decades of live production experience who understand the role litter management plays in animal welfare and performance. Let us help you develop BMPs for Precision Litter Management™ to address core environmental and health challenges. PLT Product Chemistry When PLT is applied it breaks down into sodium, hydrogen and sulfate. NaHSO–4 > Na+ + H+ + SO–4 The hydrogen lowers pH and converts ammonia into ammonium. This ammonium then binds to the sulfate portion keeping ammonia bound in the litter for the life of the flock. PLT is a safe mineral acid that breaks down into products naturally found in the environment.Environmental Chemistry

PLT is:- Biodegradable

- Non-hazardous per current DOT standards

- Ozone friendly

- The production process generates no waste and uses no solvents

- The process is analyzed in real time to prevent pollution and maximizes “atom economy” by containing all of the starting materials in the final products

- It is designed to be fully effective and has little toxicity

- It degrades after use breaking down into innocuous substances

- It is designed to minimize the potential for accidents including explosions, fires, and releases to the environment.